Digital Transformation Strategy in Manufacturing Industry – Business Transformation Trends for 2020

Author : Arul Selvan 28th Nov 2019

What is Digital Transformation? Is it just a Tech Trend?

Digital transformation is the process of using digital technologies to create new — or modify existing — business processes, culture, and customer experiences (CX) to meet changing business and market requirements. The reimagination of business for the digital age is digital transformation.

Digital Transformation in Manufacturing Industry

While leaders in manufacturing transform to optimize processes, improve the customer-centric experience, risk mitigation, innovate, grow revenues and, most of all, penetrate wholly new revenue streams with innovative business models, revolving around information and services, while slow adaptors remain to focus on just the optimization aspect.

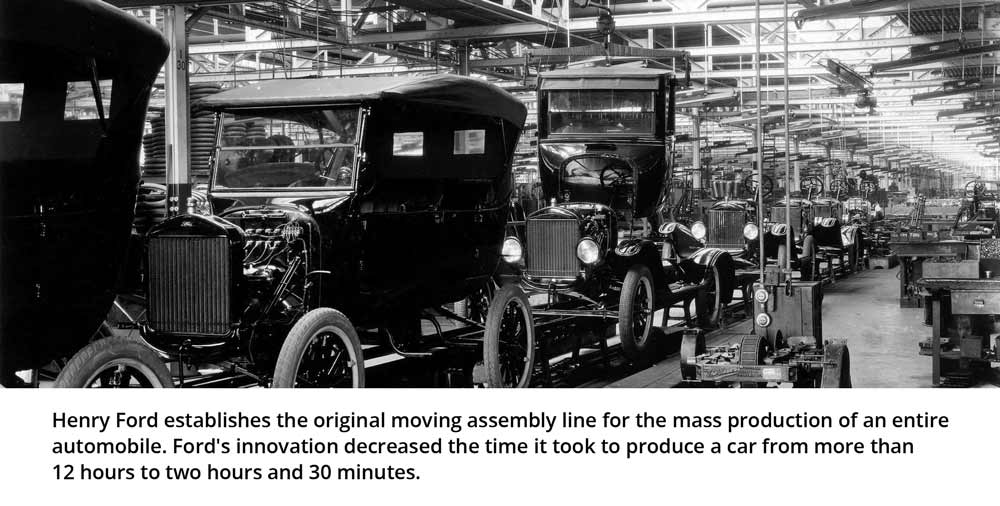

Like the Industrial Revolution changed manufacturing, digital transformation is presently responsible for changing the industry. Industrial machinery manufacturers are joining other industries and are moving to a more digitized world. Now, manufacturing companies are using technology to move from mass production to customized production, and it’s happening at a rapid pace. Since Henry Ford introduced mass production now is the time that there has been a revolution at this scale.

Buyer expectations and the arrival of connected devices and platforms are driving the persistent digitization of the manufacturing industry. While the majority of manufacturing execs recognize the significance of digital transformation strategy, A GT Nexus study found only 5 percent of those surveyed were very satisfied with their digital progress so far. The industry remains to evolve in response to the challenge of ensuring the right products are delivered at the right price to the right person through a process of improved sophistication.

Three large challenges in the manufacturing industry

Economic, geopolitical and consumption ambiguities – the demand for efficiency

As history at the end of 2016, 2017 and the next years on and beyond, The manufacturing industry is going through extremely uncertain times and unpredictability regarding consumer spending on one hand and geopolitical and economic conditions.

European companies are mobilizing to drive the Industry 4.01 vision forward, amidst the growing uncertainty (Brexit uncertainties) even faster than before. Also in other parts of the world initiatives are taken in an undeniable reality where globalization has gone from a piece of evidence for many to a source of distrust for many others.

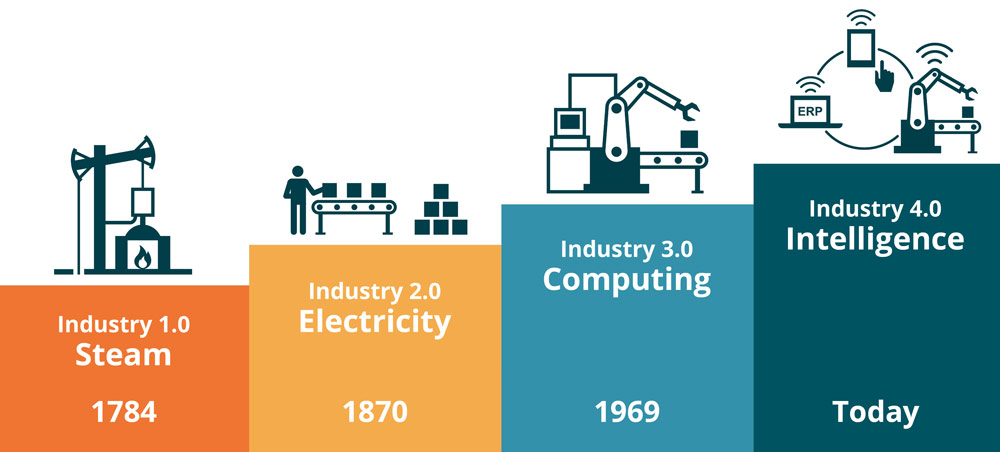

| 1 Industry 4.0 refers to a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data. Industry 4.0 encompasses IIoT (industrial internet of things) and smart manufacturing, coupling physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better-connected ecosystem for companies that focus on manufacturing and supply chain management. |

The customer factor: from speed to better products, services and customer experience

Once these efficiencies and the rather process-oriented and Industrial Internet objectives we’ve just mentioned are achieved, innovative opportunities arise and efforts are done, looking more at customer-facing optimization and innovation. Automation, optimization and efficiency- and cost-driven goals do have a customer-centric goal.

Automation multinational and Industry 4.0 pioneer ABB (Asea Brown Boveri, Swedish-Swiss multinational) took in the area of industrial robotics is a good example of how these advantages can be obtained.

Bertil Thorvaldson, Product Manager, ABB Robotics said “The power of the Internet of Things comes from the ability to collect a lot of data and convert that into useful information”

The company produces industrial robots and manufacturing services for a variety of industries, reaching from automotive to electronics. The industrial manufacturing robots they produce are not the kind of robots you would see at the Consumer Electronics Show but robotics systems as they are mainly used for manufacturing. ABB is selling such industrial robots, and provide a series of services.

Competition and the disruptive impact of manufacturers who have transformed at the core

A third element and also an unavoidable result of the first two is closer to digital transformation at the core – in the business models and the detection of new information-driven and connected revenue opportunities in the ‘as a service’ evolution.

By 2020, Manufacturers Will Capture 20% More Aftermarket Revenue by Using Product and Service Quality Measures to Enhance Customer Experiences.

According to the research of The Boston Consulting Group, released at the end of 2016, that many manufacturers see Industry 4.0 as a priority but relatively few look at the possibilities to tap into new revenue sources, let alone increase revenues.

3 Big Trends in Digital Transformation in Manufacturing

IoT and Industry 4.0

At the center of industrial transformation is IoT, accounting for more than $178 billion in 2016 and proving critical to providing businesses with a competitive edge. The manufacturing industry is heading towards IoT because of the revolutionary ways this connected technology has streamlined and simplified various manufacturing processes.

AI and Machine Learning

A machine’s ability to learn and adopt intelligent human behavior is not a new advancement. Today, these advanced algorithms are transforming the way the manufacturing industry collects information, performs skilled labor, and predicts consumer behavior. Smart factories with integrated IT systems provide relevant data to both sides of the supply chain more easily, increasing production capacity by 20%.

Quality is no longer sacrificed for efficiency, as machine learning algorithms sensors have replaced human hands, resulting in less wasted time and materials, as well as optimal accuracy and workflow. Digitizing the industry means lower cost of production, quicker turnarounds, and more efficiently meeting customer demand.

Data and Analytics

By 2020, the digital universe will increase to 44 trillion gigabytes, yet most companies are still incapable of dealing with the flow of information across their extended enterprise. International Data Corporation predicts massive fifty-fold growth in digital content from 2010 to 2020.

90% of it will be unstructured information like emails, documents, and videos. Big data adds to the content management challenge, making it larger and more complex.

To stay with these expectations, implement the best digital transformation strategy to transform the way businesses operate and share product data across the business, improving production and clarity, and reducing cost and downtime.

Currently, the manufacturing industry is the largest to implement the Internet of Things to deliver an enhanced CX to their customers. As a business owner, you must be addressing the obstacles that stop you from scaling up your business.

We, at TechAffinity, have expert developers who can develop on your digital transformation strategy and prepare you for Industry 4.0. Want to know more? Shoot your queries at media@techaffinity.com or get in touch by scheduling a meeting.